Your High pressure homogenizer images are available. High pressure homogenizer are a topic that is being searched for and liked by netizens now. You can Find and Download the High pressure homogenizer files here. Download all free photos.

If you’re looking for high pressure homogenizer pictures information connected with to the high pressure homogenizer keyword, you have visit the ideal site. Our website frequently gives you suggestions for downloading the highest quality video and image content, please kindly search and find more enlightening video articles and graphics that fit your interests.

High Pressure Homogenizer. High pressure homogenizers HPH also known as Gaulin homogenizers after the inventor. A homogenizer consists of a high pressure piston pump downstream of which a homogenizing valve is installed in which the homogenization process takes place of the treated product. A homogenizer is generally needed when high-efficiency homogenization is required. A high-pressure homogenizer is a pump with a homogenization device.

From pinterest.com

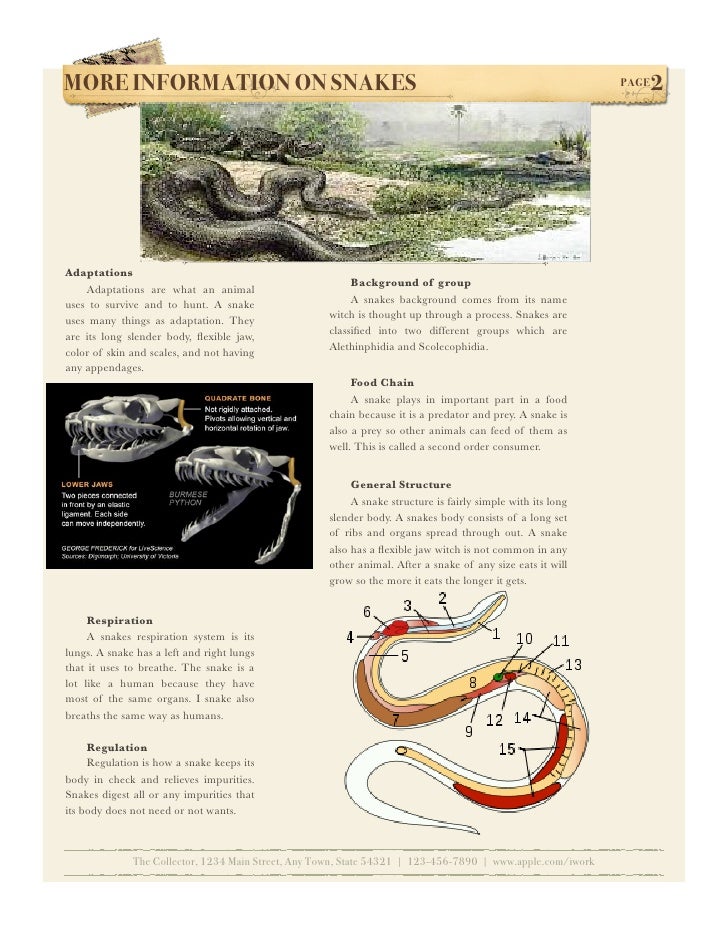

From pinterest.com

Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. A high-pressure homogenizer is a pump with a homogenization device. High-pressure homogenizers are most commonly used for. This act causes high shear a large pressure drop and cavitation all of which act to homogenize the sample. High pressure homogenizers can accomplish this task. A homogenizer consists of a high pressure piston pump downstream of which a homogenizing valve is installed in which the homogenization process takes place of the treated product.

Ad Shop Devices Apparel Books Music More.

Thanks to its dual head design it provides an improved flowrate of up to 70 Lh 50Hz and up to 84 Lh 60Hz with a nearly constant pressure profile. A homogenizer consists of a high pressure piston pump downstream of which a homogenizing valve is installed in which the homogenization process takes place of the treated product. When your workload ranges from research to medium sized production batches the PSI-40 is the best choice on the market. High Pressure Homogenizers BEE International manufactures high pressure homogenizers to expand mixingblendinggrinding process capabilities for particle size reduction and cell rupture applications. This act causes high shear a large pressure drop and cavitation all of which act to homogenize the sample. Our range of homogenizers covers up to a flow rate of 60000 lh and a maximum pressure of 2000 bar.

Source: pinterest.com

Source: pinterest.com

Ad Shop Devices Apparel Books Music More. For example IKA high pressure homogenizer HPH is used for the homogenizing of dairy products disintegration of cellulose in vegetables production of gel systems in the pharmaceutical industry and for cell disintegration in the biotechnology. Our range of homogenizers covers up to a flow rate of 60000 lh and a maximum pressure of 2000 bar. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. This process can help to create a balance between customers satisfaction and their required nutritious consumption.

Source: pinterest.com

Source: pinterest.com

In a high-pressure homogenizer the dispersion of two liquids oily phase and aqueous phase or finely divided solids in liquid is achieved by forcing their mixture through a small inlet orifice at very high pressure 500 to 5000 psi which subjects the product to intense turbulence and hydraulic shear resulting in extremely fine particles of emulsion suspension. High-pressure homogenizers consist of a tank to which high pressure is applied in order to force the liquid sample contained therein through a valve or membrane with very narrow slits. Free Shipping on Qualified Orders. This process can help to create a balance between customers satisfaction and their required nutritious consumption. High pressure processing equipment enables food producers to retain the color flavor and nutrition values of the products and improve texture.

Source: pinterest.com

Source: pinterest.com

This process can help to create a balance between customers satisfaction and their required nutritious consumption. Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. A high-pressure positive displacement pump connected to our homogenizers forces liquid through a specially engineered orifice at pressures to 6500 PSI. In a high-pressure homogenizer the dispersion of two liquids oily phase and aqueous phase or finely divided solids in liquid is achieved by forcing their mixture through a small inlet orifice at very high pressure 500 to 5000 psi which subjects the product to intense turbulence and hydraulic shear resulting in extremely fine particles of emulsion suspension. High-pressure homogenizers consist of a tank to which high pressure is applied in order to force the liquid sample contained therein through a valve or membrane with very narrow slits.

Source: pinterest.com

Source: pinterest.com

A homogenizer consists of a high pressure piston pump downstream of which a homogenizing valve is installed in which the homogenization process takes place of the treated product. When your workload ranges from research to medium sized production batches the PSI-40 is the best choice on the market. Free Shipping on Qualified Orders. We also bring for our clients High Pressure Homogenizers such as Homogenizers for Fruit Juice Homogenizers for Ice Cream Homogenizer for Dye Chemical Standard Homogenizer Laboratory Homogenizer Fruit Juice Homogenizers Ice Cream Homogenizers Low Pressure Homogenizers and High Pressure Homogenizers. On the other hand HPH also known as dynamic high-pressure homogenization or high-pressure valve homogenization is an emerging continuous flow process technology enabling the homogenization and pasteurization and in some cases sterilization of fluids in one single step 122 210 while the fluid is being subjected to high pressure for less than a second 166 187.

Source: pinterest.com

Source: pinterest.com

Ad Shop Devices Apparel Books Music More. This process can help to create a balance between customers satisfaction and their required nutritious consumption. A high-pressure positive displacement pump connected to our homogenizers forces liquid through a specially engineered orifice at pressures to 6500 PSI. High pressure homogenizers can accomplish this task. Free Shipping on Qualified Orders.

Source: pinterest.com

Source: pinterest.com

Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. On the other hand HPH also known as dynamic high-pressure homogenization or high-pressure valve homogenization is an emerging continuous flow process technology enabling the homogenization and pasteurization and in some cases sterilization of fluids in one single step 122 210 while the fluid is being subjected to high pressure for less than a second 166 187. Free Shipping on Qualified Orders. High pressure homogenizers can accomplish this task. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap.

Source: pinterest.com

Source: pinterest.com

A homogenizer consists of a high pressure piston pump downstream of which a homogenizing valve is installed in which the homogenization process takes place of the treated product. The homogenizer consists of a high pressure pump and a homogenizing. This process can help to create a balance between customers satisfaction and their required nutritious consumption. We serve pharmaceutical biotech cannabis. A high-pressure homogenizer is a pump with a homogenization device.

Source: pinterest.com

Source: pinterest.com

A high-pressure homogenizer is a pump with a homogenization device. On the other hand HPH also known as dynamic high-pressure homogenization or high-pressure valve homogenization is an emerging continuous flow process technology enabling the homogenization and pasteurization and in some cases sterilization of fluids in one single step 122 210 while the fluid is being subjected to high pressure for less than a second 166 187. Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. A homogenizer is generally needed when high-efficiency homogenization is required.

Source: pinterest.com

Source: pinterest.com

Ad Shop Devices Apparel Books Music More. On the other hand HPH also known as dynamic high-pressure homogenization or high-pressure valve homogenization is an emerging continuous flow process technology enabling the homogenization and pasteurization and in some cases sterilization of fluids in one single step 122 210 while the fluid is being subjected to high pressure for less than a second 166 187. High-pressure homogenizers consist of a tank to which high pressure is applied in order to force the liquid sample contained therein through a valve or membrane with very narrow slits. For example IKA high pressure homogenizer HPH is used for the homogenizing of dairy products disintegration of cellulose in vegetables production of gel systems in the pharmaceutical industry and for cell disintegration in the biotechnology. High pressure processing equipment enables food producers to retain the color flavor and nutrition values of the products and improve texture.

Source: pinterest.com

Source: pinterest.com

High pressure homogeniser is a general term used to describe a piece of equipment that forces a stream of liquid sample through a system which applies a number of forces to homogenise the sample that is to reduce the particle size of its components. For example IKA high pressure homogenizer HPH is used for the homogenizing of dairy products disintegration of cellulose in vegetables production of gel systems in the pharmaceutical industry and for cell disintegration in the biotechnology. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. On the other hand HPH also known as dynamic high-pressure homogenization or high-pressure valve homogenization is an emerging continuous flow process technology enabling the homogenization and pasteurization and in some cases sterilization of fluids in one single step 122 210 while the fluid is being subjected to high pressure for less than a second 166 187. In a high-pressure homogenizer the dispersion of two liquids oily phase and aqueous phase or finely divided solids in liquid is achieved by forcing their mixture through a small inlet orifice at very high pressure 500 to 5000 psi which subjects the product to intense turbulence and hydraulic shear resulting in extremely fine particles of emulsion suspension.

Source: tr.pinterest.com

Source: tr.pinterest.com

Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. This process can help to create a balance between customers satisfaction and their required nutritious consumption. Free Shipping on Qualified Orders. Ad Shop Devices Apparel Books Music More. Homogenising Systems extensive range of high pressure homogenisers provide exceptional processing with highly controllable systems offering market leading pressure capability and processing versatility with both piston gap and micro-channel processing options.

Source: pinterest.com

Source: pinterest.com

We serve pharmaceutical biotech cannabis. High pressure homogeniser is a general term used to describe a piece of equipment that forces a stream of liquid sample through a system which applies a number of forces to homogenise the sample that is to reduce the particle size of its components. High-pressure homogenizers are most commonly used for. Ad Shop Devices Apparel Books Music More. This process can help to create a balance between customers satisfaction and their required nutritious consumption.

Source: pinterest.com

Source: pinterest.com

Ad Shop Devices Apparel Books Music More. Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. We serve pharmaceutical biotech cannabis. A homogenizer is generally needed when high-efficiency homogenization is required. High pressure processing equipment enables food producers to retain the color flavor and nutrition values of the products and improve texture.

Source: pinterest.com

Source: pinterest.com

High-pressure homogenizers consist of a tank to which high pressure is applied in order to force the liquid sample contained therein through a valve or membrane with very narrow slits. Ad Shop Devices Apparel Books Music More. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. For example IKA high pressure homogenizer HPH is used for the homogenizing of dairy products disintegration of cellulose in vegetables production of gel systems in the pharmaceutical industry and for cell disintegration in the biotechnology. Thanks to its dual head design it provides an improved flowrate of up to 70 Lh 50Hz and up to 84 Lh 60Hz with a nearly constant pressure profile.

Source: pinterest.com

Source: pinterest.com

Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. For example IKA high pressure homogenizer HPH is used for the homogenizing of dairy products disintegration of cellulose in vegetables production of gel systems in the pharmaceutical industry and for cell disintegration in the biotechnology. The homogenizer consists of a high pressure pump and a homogenizing. High-pressure homogenizers are most commonly used for.

Source: co.pinterest.com

Source: co.pinterest.com

In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. This act causes high shear a large pressure drop and cavitation all of which act to homogenize the sample. In this type of equipment homogenization is achieved by forcing the mixture to flow at high velocity through a narrow gap. When your workload ranges from research to medium sized production batches the PSI-40 is the best choice on the market. A high-pressure homogenizer is a pump with a homogenization device.

Source: in.pinterest.com

Source: in.pinterest.com

The product enters the pump block and is pressurized by the piston pump. Our range of homogenizers covers up to a flow rate of 60000 lh and a maximum pressure of 2000 bar. A high-pressure positive displacement pump connected to our homogenizers forces liquid through a specially engineered orifice at pressures to 6500 PSI. When your workload ranges from research to medium sized production batches the PSI-40 is the best choice on the market. Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron.

Source: pinterest.com

Source: pinterest.com

A homogenizer is generally needed when high-efficiency homogenization is required. Free Shipping on Qualified Orders. The homogenizer consists of a high pressure pump and a homogenizing. Our high pressure homogenizers use no moving parts to create fine emulsions and dispersions with droplet sizes below 1 micron. High pressure homogenizers HPH also known as Gaulin homogenizers after the inventor.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title high pressure homogenizer by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.